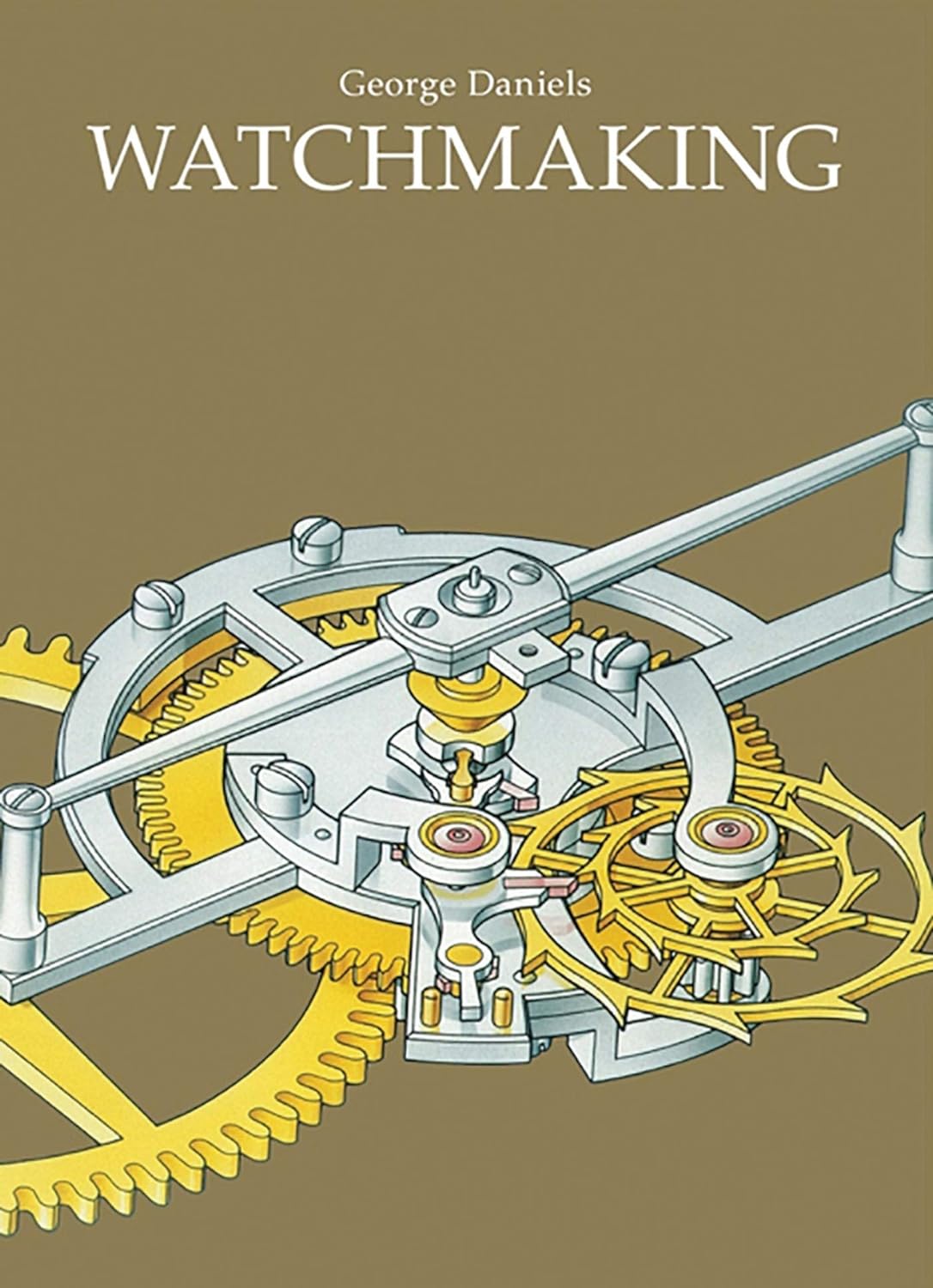

Watchmaking

Watchmaking by George Daniels is a seminal work that delves into the intricate art and science of crafting timepieces. First published in 1981, this comprehensive guide has inspired and educated both aspiring and experienced watchmakers for decades.

About the Author: George Daniels (1926–2011) was a renowned British horologist celebrated for his exceptional craftsmanship and innovation in watchmaking. He is perhaps best known for inventing the coaxial escapement, a significant advancement in mechanical watch technology. Daniels’ profound understanding of horology and dedication to the craft have left an indelible mark on the industry.

Content Overview: The book meticulously outlines the process of creating a precision timekeeper, covering topics such as:

Case Making and Finishing

Workshop Setup

Tools and Techniques

Component Fabrication

Escapements

Creating a mechanical watch

Creating a mechanical watch is a meticulous process that blends artistry and precision engineering. Here’s an overview of the key steps involved:

1. Design and Prototyping

The journey begins with designers crafting detailed blueprints that outline the watch’s aesthetics and functionality. These designs are transformed into prototypes to assess the feasibility and make necessary adjustments.

2. Material Selection

Choosing high-quality materials is crucial for durability and style. Common materials include stainless steel for cases, sapphire crystal for watch faces, and various metals for internal components.

3. Manufacturing the Movement

The movement, or the watch’s engine, is assembled from tiny, precisely crafted parts. This intricate assembly requires exceptional skill to ensure accurate timekeeping.

4. Dial and Hands Installation

The dial is carefully placed onto the movement, and the hands are attached with precision to ensure they align perfectly and move without obstruction.

5. Case Assembly

The assembled movement and dial are encased, protecting the delicate components from dust and moisture. This step often involves sealing the case to ensure water resistance.

6. Quality Control and Testing

Each watch undergoes rigorous testing to verify its accuracy, durability, and water resistance. This phase ensures that the timepiece meets all quality standards before reaching consumers.

This process highlights the dedication and expertise required to produce a high-quality mechanical watch, reflecting both technological prowess and artistic expression.

The Watchmaking Book is available from these international retailers.